Blast/Impact Resistant

In today’s increasingly unstable political and social environment, safety and security has become a top concern with facility owners storing petroleum and other flammable liquids.

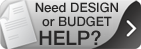

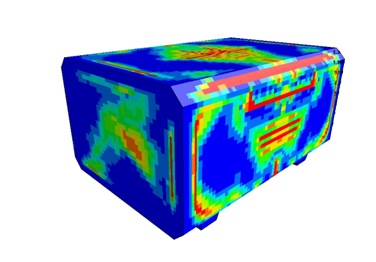

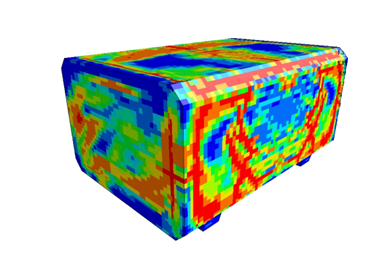

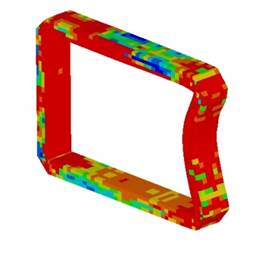

With this heightened awareness of security in mind, ConVault Inc. recently retained Karagozian & Case (K&C), a World Leader in Blast Consulting and Blast-Resistant Design, to complete a Blast Effects Analysis (BEA) on the design of the ConVault protected Aboveground Storage Tank (AST). ConVault AST’s feature six inches of reinforced concrete surrounding both the primary and secondary containment of the fuel tank.

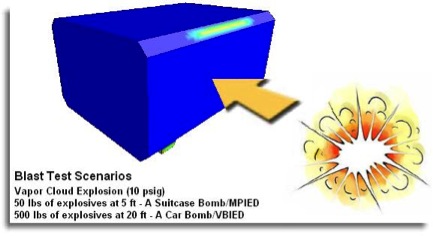

Three different threat scenarios were investigated to determine the inherent blast resistance of the ConVault design. These scenarios were chosen to reflect blast distances recommended in FEMA’s Reference Manual to Mitigate Potential Terrorist Attacks Against Buildings.

- a blast from a vapor cloud such as might accumulate at a refinery with explosive pressures at 10 psig (the higher end of the range of expected pressures);

- a blast from 50 lbs of High Explosive (HE) TNT as might be carried by a typical suicide bomber (Man Portable Improvised Explosive Device); and

- a blast from 500 lbs of High Explosive (HE) TNT representing a typical car bomb (Vehicle Borne Improvised Explosive Device).

A 2000 gallon tank was used to represent a typical ConVault tank design. The ConVault successfully met the two criteria for a successful test, which are:

- the tank would not move more than two inches, and

- the integrity of the primary tank would not be compromised ( no resulting fuel leaks from the primary tank).

Overall, the Blast Effects Analysis indicates that the ConVault AST is very resistant to the effects of the blast loads considered. The mass provided by the reinforced concrete outer shell protected the steel tank extremely well, and greatly enhanced the resistance to all blasts. It withstood the vapor cloud blast, a 50 lb TNT blast centered at 5 feet from the tank, and a 500 lb TNT blast centered at 20 feet from the tank.

The magnitude of these blasts at the respective proximities would be expected to destroy and/or relocate lighter, less robust fuel storage tanks. However, the ConVault AST will not only remain in place, it will survive with no fuel leakage from the primary tank.

The strength and durability of the primary steel tank enclosed in steel reinforced concrete allows ConVault to provide unsurpassed protection against blast and impact damage. ConVault excels where other tanks fail when it comes to protecting the fuel containment steel tank from puncture due to impact or explosive blast. The exterior steel reinforced concrete is engineered to prevent puncture and withstand the impact from transportation related to facility operations such as forklifts and motor vehicles.

UNMATCHED PROTECTION OF THE PRIMARY TANK AND SECONDARY CONTAINMENT

Convault encases BOTH THE PRIMARY TANK AND THE SECONDARY CONTAINMENT in 6” of steel-reinforced concrete that outperforms stringent UL 2085 requirements for blast, fire, and ballistic impact protection. From coast to coast across the USA and around the world you will find countless examples of Convault tanks reliably performing through extreme weather and catastrophic events. That’s one reason why Convault is the preferred tank at military, paramilitary, and public safety installations. A recent study by Karagozian and Associates demonstrated how the inertia and mass of Convault’s steel reinforced, monolithic concrete entombment protects the tank from blast and impact.

Convault®tanks are designed to have a low center of gravity that can withstand vehicle impact and tipping during earthquakes and other natural disasters. Convault® tanks have withstood even phenomenal tests such as C-130 aircraft impact at Dobbins AFB in Georgia, Hurricane Andrew and the 1989 Loma Prieta earthquake.

Bullet Resistance

Convault® tanks withstand bullet resistance tests in compliance with UFC SECTION (79-7) APPENDIX # A-II-F-1 and UL 2085 Standard for Protected tanks.